Full Port 12" Class 600 Lubricated Plug Valve

Basic Info.

| Model NO. | AFPLV-10 |

| Inspection & Test | API 598 |

| Sealing | Soft Sealing or Metal Sealing |

| Design & Manufacture | API 6D, API 599 & ASME B16.34 |

| Painting | Std |

| Materials | Wcb, Lcb, Lcc, Ss, Duplex, Alloy 20 etc. |

| Operation | Handle/Worm Gear Pneumatic/Electric |

| Connection Ends | RF, NPT, Bw, Sw |

| Flange End | ASME B 16.34 |

| Pressure Rating | Class 150-2500 Lb |

| Certificates | ISO, CE, API etc. |

| Transport Package | Plywood Case |

| Specification | 1/2"-36" |

| Trademark | AFC TECH OR OEM |

| Origin | China |

| HS Code | 8481804090 |

| Production Capacity | 1500 Tons/ Year |

Product Description

Plug Valve Brief Introduction:

Plug Valve is also named taper plug valve or taper valve. Not like ball valve, gate valve and globe valve, there are manymanufacturers and supplier in China, plug valve is a kind of relatively narrow product. It is not easy to find the right plug valvesupplier. Luckily, you meet us. AFC is the one who has more than 10 years exporting experience and concentrated on worldmarket since its set up. In the past, China imported those famous brand plug valves, but today, with fast development of economy and technology, Made In China has become trendy. Our double block and bleed plug valve, eccentric plug valve, lubricated plug valve, sleeved plug valve etc. have similar quality with branded products but the price will be much more competitive. Welcome to consult us.

Inverted Pressure Balance Lubricated Plug Valve

Lubricated is the most popular one among all the plug valves. Inverted pressure balance lubricated plug valve according to ANSI is applicable to the cutting and connection of pipelines medium that are used in various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, electric power industry etc. under nominal pressure of Class 150lb-900Lbs and working temperature of -29-180 Deg C.

Inverted pressure balance lubricated plug valve main structural features:

| 1. It has logical structure, reliable seal, excellent performance and nice design. |

| 2. It has the structure of flip-chip balanceable pressure and light on/off operation. |

| 3. An oil groove is set between valve body and seal surface, which may infuse the seal grease to increase the seal capability. |

| 4. The part material and flange dimension may be selected according to current operating condition and users requirement, so that meet the requirements of various engineering. |

Inverted pressure balance lubricated plug valve technical specifications:

| Structural formation:: Bolted Cover |

| Operation: Manual, Electric-Actuated. |

| Design Standard: API 599, API 6D |

| Face to Face: ASME B16.10 |

| Flange Ends: ASME B16.5 |

| Test & Inspection: API598, API 6D. |

| Suitable Temp: Below 80 Deg C / 300 Deg C. |

| Materials:WCB,WCC,LCB,LCC,CF8,CF8M,CF3,CF3M,A105,LF2,F304,F316,F304L,F316L,F51,F53,F55,INCONEL625,F904L,F44, Carbon Steel, Stainless Steel, Inconel, Duplex, Alloy 20, Hastelloy, Monel etc. |

Other Plug Valve Show:

Picture 2: Double Bleed and Block Plug Valve Picture 3: Twin Seal Plug Valve Picture 4: Eccentric Plug Valve Picture 5: Regular Port Eccentric Plug Valve

Advantages:

1. Focusing on exporting, more than 80% products are sold worldwide.

2. Provide Full Sets of Solutions for your various industrial needs.

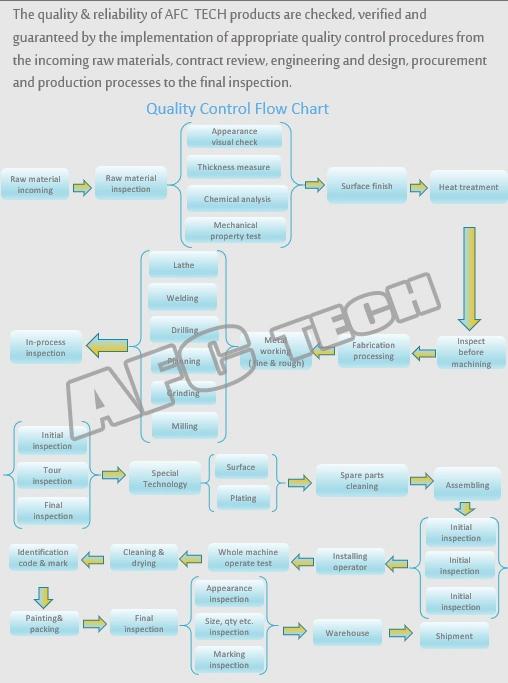

3. Strict & Traceable Quality Control System

4. Simplified & Effective Managing System

5. Competitive Price & On-time Delivery, with Integrated Services

Foundry (Castings and forgings)

Quality Control:

Inspection & Test:

Packing and Shipment:

Application:

Valves serve a variety of purposes in the industrial, engineering, manufacturing and scientific communities. Selecting the right valve can determine the success or failure of the system or process.

The main purpose of a valve is to control media flow through a system. The valve may be used to start, stop, or throttle the flow to ensure safe and efficient operation of the process. Valves play a large role in most industries. With high quality and excellent service, AFC TECH valves are widely used Oil & gas industry, refinery & petrochemical industry, off shore, power generation, mining industry, pulp and paper, water treatment etc.

Aftersales Services:

1. For each batch of goods we made, we'll furnish MTC to show the goods are 100% inspected & tested, and qualified to use.

2. Full sets of parts and accessories in the AFC TECH of the technical drawing can be supplied, in case of any possible repair or change.

3. Even our goods are made under strict quality control system, but still can not 100% avoid unexpected conditions or quality problems forever, that's why we furnish a warranty of 18 months from shipment date, during this period, we'll take responsibility for the repair, change or return for free due to quality problems.

FAQ:

1. Q: Are you a manufacturer or a trading company?

A: We are a production and marketing company, industry and trade integration. Our factories are responsible for manufacturing, we are dealing with all exporting business.

2. Q: Do you have any international certificates?

A: Yes, our factories have CE and ISO etc. certificates.

3

Q: Do you have any export experience?

A: Yes, we have been exported a lot worldwide. More than 80% of our products are

for exporting.

4

Q: Do you have any quality certificates?

A: Yes, EN 10204 3.1 Material Certificate will be supplied together with delivery. Certificate of Origin shall be supplied upon client's request

5. Q: Do you have any Non-destructive Test?

A: Yes, we have upon the customer's requests.

6. Q: Can you manufacture valves with our brand?

A: Yes, we can manufacture with our own brand or OEM.

7. Q: Do you have any guarantee?

A: Yes, we warrant our products against defects from faulty manufacturing for 12 months from the initial date of installation, or within 18 months after shipment, subject to whichever to be earlier.